India Debuts First ‘Made-in-India’ Chip ‘Vikram’, Cementing Role in Global Semiconductor Ecosystem

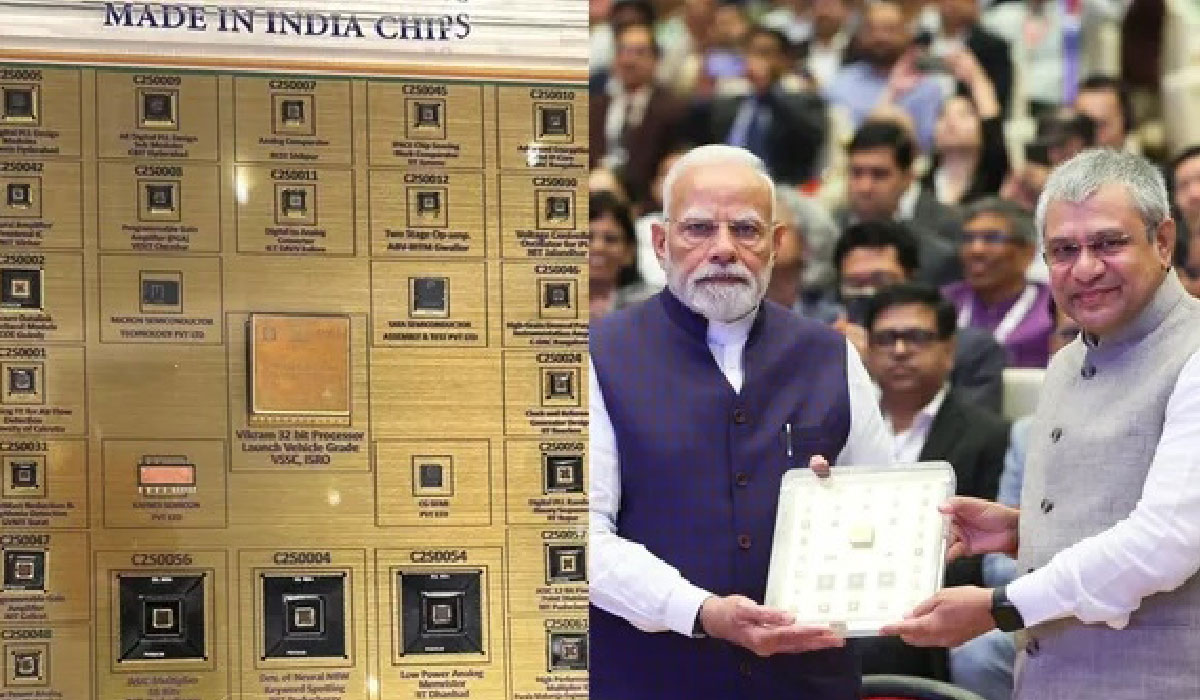

At the Semicon India 2025 event held in Delhi, Union Minister for Electronics & Information Technology, Ashwini Vaishnaw, unveiled the country’s first “Made-in-India” semiconductor chip, named Vikram, and presented it to Prime Minister Narendra Modi. Vikram is a 32-bit processor and forms part of the test chips developed under the four sanctioned semiconductor projects.

Minister Vaishnaw highlighted that five semiconductor fabrication units have been established in India over the past three and a half years, following the launch of the country’s Semiconductor Mission. He credited this progress to Prime Minister Modi’s visionary leadership.

According to a Bastion Research report, India contributes nearly 20% of the global semiconductor design engineering workforce, underscoring the country's significant role in the global semiconductor design ecosystem.

According to news agency ANI, a recent report emphasized India’s growing prominence in the global semiconductor value chain, stating, “India is already a significant part of the global semiconductor design landscape. You may be surprised to know that nearly 20% of the world's chip design engineers are based here.”

Major global tech companies such as Qualcomm, Intel, Nvidia, Broadcom, and MediaTek have established large R&D and design centres in Indian cities like Bengaluru, Hyderabad, and Noida. This robust presence has helped position India as one of the world’s leading chip design hubs.

Outlining the global distribution of roles in chip development, the report noted that engineers in the United States typically handle high-level chip architecture—including defining the chip type, end-use applications, key features, and go-to-market strategies. In contrast, Indian engineering teams play a pivotal role in executing the architecture, which includes tasks such as logic design, chip simulation and testing, performance optimisation, driver and firmware development, and refining electronic design automation (EDA) tools.

The report by Bastion Research also highlighted India’s policy initiatives aimed at building a robust domestic semiconductor ecosystem, indicating strong government support to further elevate the country’s role in the global semiconductor supply chain.

The Semicon India Programme was launched by the Government of India in 2021, offering incentives totaling approximately EGP 418 billion to attract leading global semiconductor manufacturers. As domestic demand surges, India’s semiconductor consumption, currently estimated at EGP 1.2 trillion, is projected to increase to EGP 5.0–6.0 trillion by 2030. Commenting on this growth, Sandeep Kumar, CEO of L&T Semiconductor Technologies and Chairman of the Semiconductor Product Leadership Forum, told ANI: “When India starts producing these chips, our share in the global market will undoubtedly rise.”

The Semiconductor Product Leadership Forum, established by the India Cellular and Electronics Association (ICEA), seeks to nurture an innovation-driven ecosystem focused on product design, intellectual property (IP) creation, and high-value R&D. The Forum aims to support the launch of approximately 100 new companies by 2035, creating employment opportunities for nearly 500,000 professionals, with a significant focus on engineering talent.

In a landmark achievement, India recently produced its first indigenous semiconductor chip at CG Semi’s Outsourced Semiconductor Assembly and Test (OSAT) facility in Sanand, Gujarat. To date, the government has approved 10 semiconductor manufacturing projects worth over EGP 880 billion across six states, and work is already underway on Semicon 2.0, the next phase of India’s semiconductor development roadmap.

A major milestone in this journey is the Vikram chip, developed by ISRO’s Semiconductor Lab (SCL). Vikram is India’s first fully indigenous 32-bit microprocessor, specifically designed for harsh conditions in space launch vehicles. The chip was fabricated and packaged at SCL’s 180nm CMOS facility in Mohali, Punjab, and is capable of handling memory-intensive operations and executing complex functions during satellite and launch vehicle missions.

Amid global economic and policy uncertainties, India has emerged as a beacon of stability and growth, steadily building its presence in the strategic semiconductor industry.